Description

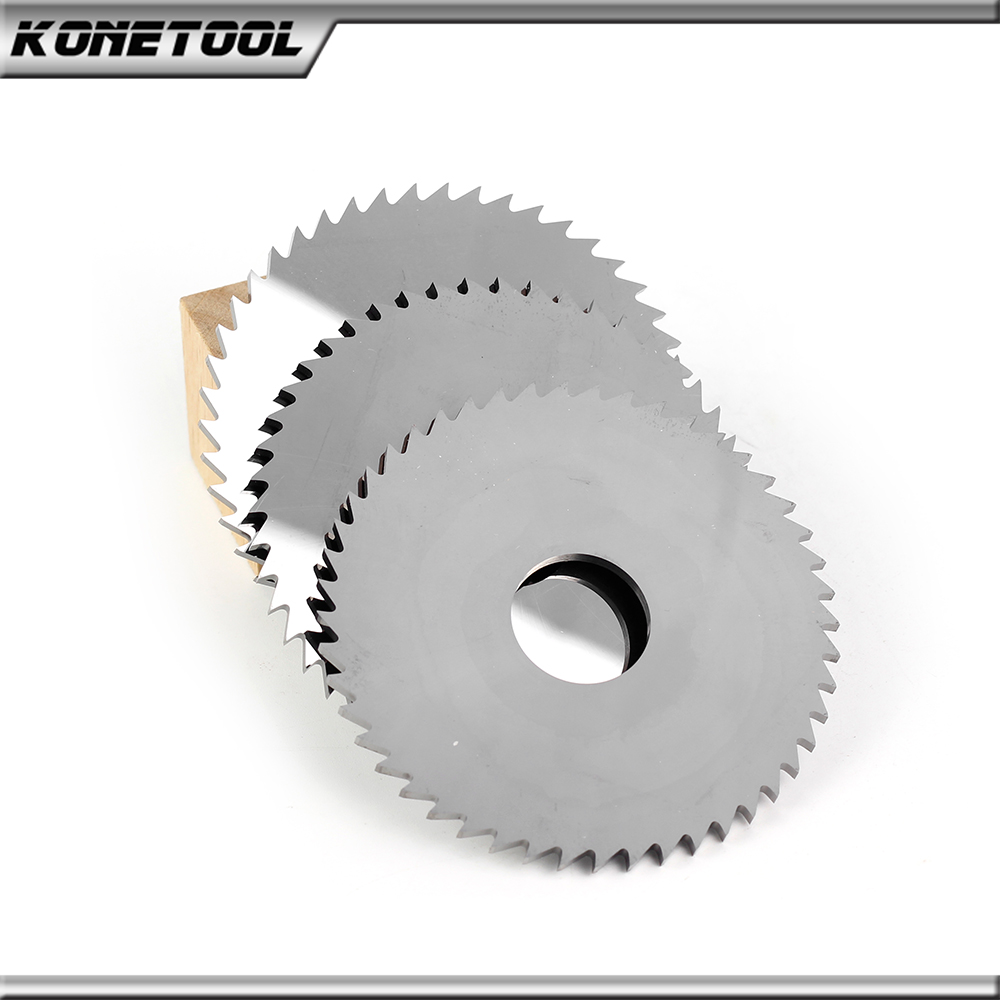

Slitting saws are commonly used on milling machines for slotting fragile and hard materials. Carbide saw blades are especially suitable for milling or grooving abrasive or hard materials like steel and alloys. Compared with HSS slitting cutters, solid carbide slitting saws are more rigid and can bear extreme heat in high-speed applications, allowing for faster feeds and speed.

Konetool supplies carbide slitting saws to clients across many industries, including automotive, construction, aerospace, and jewelry production. Used with an arbor, our carbide slitting saw has been proven to be reliable for cutting screws, bolts, rods, thin wall tubes, jewelry, and other applications. Our slitting cutters are made from GS22 tungsten carbide, featuring outstanding cutting efficiency and durability.

KONETOOL Carbide Slitting Saw Features:

- Sharp cutting edge and increased tool life due to top-quality material.

- Superior surface finish and remarkable precision.

- Ground side clearance for free cutting and no binding.

- Gound to a mirror-like finish to reduce drag.

- Good for slotting, slitting, and cutoff.

- Competitive Price.

- Guaranteed global delivery.

- Customization is available.

| Konetool Grade | Grain Size | Density (g/cm³) | Hardness (HRa) | T.R.S (N/m㎡) |

| GS22 | Sub-Micron | 14.34 | 92.1-92.5 | 2900 |

Specification:

| Diameter (mm) | Arbor Hole Diameter (mm) | Thickness (mm) | Number of Teeth |

| 60 | 16 | 1.0 | 48 |

| 60 | 16 | 1.2 | 48 |

| 60 | 16 | 1.5 | 48 |

| 60 | 16 | 2.0 | 48 |

| 180 | 25.4 | 1.2 | 250 |

| 180 | 20 | 1.2 | 250 |

| 200 | 25 | 1.6 | 240 |

Machine:

Milling machines, CNC milling machines

Cutting Material:

Stainless steel, Aluminum, Cast iron, Titanium, Brass, Copper, Plastics, etc.

FAQ:

- How can I make the payment?

We accept various payment methods, including T/T (bank transfer), PayPal, Western Union, and L/C (Letter of Credit) for larger orders. Payment terms are typically 30% deposit in advance and 70% balance before shipment. - What are the shipping options and delivery times?

We support FOB, CIF, and DDP shipping terms depending on your preference. we usually ship via express courier like DHL, FedEx, or UPS. Lead time for bulk orders is generally 15–35 days, depending on quantity and customization requirements. - How do you ensure product quality?

We have a strict quality control system in place. All products are inspected at every stage of production, We have own quality inspection team and laboratory, along with advanced equipment to ensure the qualification rate of our products up to 99%.and can provide test reports or certificates upon request. - Can I customize the product or packaging?

Yes, we offer OEM and ODM services. You can customize the product design, . Just let us know your requirements,CAD,Step Drawings,or send sample Our team will assist you throughout the process. - What is your after-sales service policy?

If you encounter any quality issues, please contact us with photos or videos. We will evaluate the situation and provide replacements, spare parts, or refunds as appropriate.

We are very happy to offer our best solutions to help our customers, so if there are any questions you have about our slitting cutters, feel free to contact us.