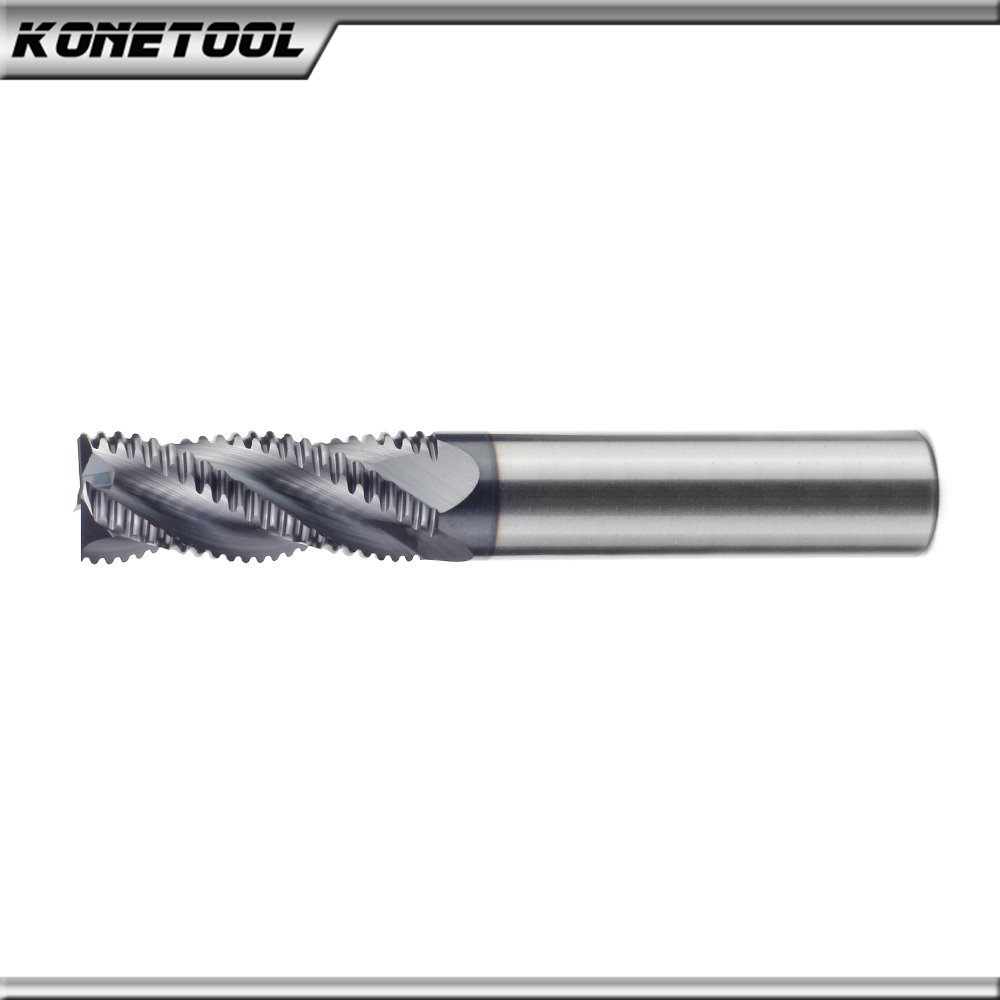

Solid Carbide Roughing Milling Cutter is highly efficient tools used for quickly removing a large amount of material. Konetool’s milling cutters are manufactured on 5-axis CNC lathes and are characterized by high hardness and high wear resistance, providing a long service life and excellent cutting performance. They are suitable for processing various wood materials, such as MDF, multi-layer boards, and hardwoods, etc. Moreover, these milling tools usually have a helical cutting edge, which helps to more effectively discharge chips, reduce resistance during the cutting process, and thereby improve processing efficiency.

Material: Solid tungsten carbide.

Used on: CNC routing, carving, and milling machines.

Shank: 8.0mm,10.0mm,12.0mm,12.7mm,16.0mm.

Request a quote for further information, including minimum order quantity (MOQ), price, delivery, and more.