Types of Cold Saw Blades Explained

When it comes to metal cutting, several options can create nice cuts, such as bandsaw, chop saw, and cold saw. Compared to the other two types of saws, cold saws are quite costly. However, cold saws can result in cleaner and more accurate cuts. Choosing the right cold saw blades is crucial for the metal-cutting process due to the different requirements and specifications of the project. There are two types of cold saw blades: high-speed steel (HSS) and carbide-tipped. By understanding the differences between these two types of blades, we can better determine which blade to use for our metal cutting job. First of all, let’s explore further information about cold saw blades.

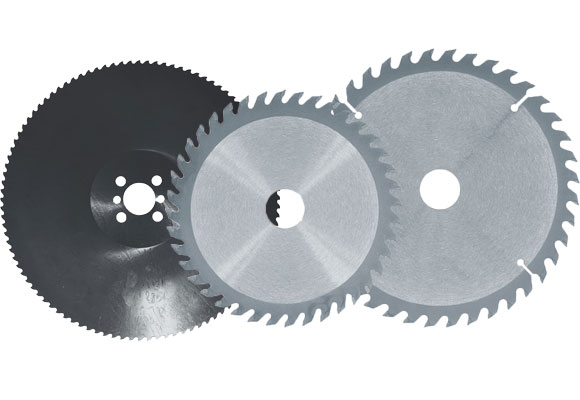

Cold saw blades: What is it?

In fact, cold saw blades are circular saw blades that are specifically designed for cutting metal, so they are also called circular metal cutting saw blades. Like circular saw blades in woodworking, cold saw blades are toothed and cut workpieces by rotation. However, cold saw blades run at a very low speed, usually below 200 RPM. Cold saw blades usually work with manual, semi-auto, or fully automatic cold saw machines. Unlike an abrasive chop saw, a cold saw creates a cool finish since heat is carried away by chips during the process. Cold saw blades are used for cutting both nonferrous and ferrous metals, including mild steel, stainless steel, aluminum, copper, and more.

HSS cold saw blades

(Image Source: cmtorangetools.com)

As the name suggests, HSS cold saw blades are made from high-speed steel, ensuring the hardness, wear resistance, and shock resistance of the blade. They feature a variable tooth pitch to minimize vibrations and ensure smooth cutting. The tooth geometry helps in chip evacuation and reduces heat build-up during the cutting process. When dull or damaged, HSS blades can be sharpened and become sharp again. Coatings are employed to extend the lifespan of HSS cold saw blades, such as TiN and TiAlN.

Carbide-tipped cold saw blades

Carbide-tipped cold saw blades consist of alloy steel body and carbide inserts that are brazed to blade tips. Thanks to tungsten carbide tips, these blades are much more durable than HSS cold saw blades. Carbide is more heat-resistant than HSS, thus carbide-tipped blades can rotate at a higher speed than HSS blades. All carbide tips are precisely ground by the grinding machine to form perfect cutting angles. Tungsten carbide tips don’t need frequent resharpen, thus reducing downtime and improving productivity.

Konetool is a quality supplier of carbide-tipped cold saw blades that are ideal for cutting aluminum. If you are looking for premium carbide-tipped circular metal cutting saw blades, please contact us to request a quote.