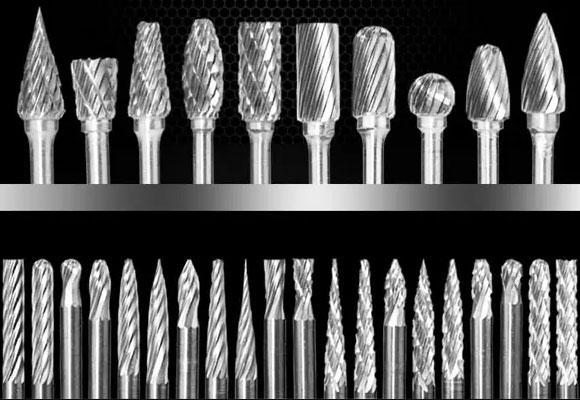

What Are Carbide Burr Shapes?

Carbide burrs, also known as die grinder bits, carbide rotary burrs, or rotary files, are frequently used in metalworking for deburring, contouring, carving, grinding, and cutting. They help remove sharp edges from hard metal pieces, resulting in the required smoothness. Carbide burrs are widely used in industries like metal sculpting, aerospace, automotive, dental, and more. A carbide rotary burr consists of a tungsten carbide head and a steel shank. The head comes in various shapes and each carbide burr shape is designed for specific purposes. In this article, we will explain these carbide burr shapes and their applications.

Shape A: Cylindrical Plain End

Unlike a cylindrical end cut burr, a cylindrical plain end burr isn’t equipped with a cutting edge at the end. Applications of a cylindrical (plain end) shape burr include:

- Enlarging notches or holes

- Removing broken screws

- Chamfering

- Deburring

- Creating clean finishes for narrow and small spaces

- Creating intricate details in various materials

Shape B: Cylindrical End Cut

A cylindrical end cut carbide burr features a cutting edge at the end side, making it a versatile shape of carbide burr.

- Removing surface flaws

- Creating curves

- Carving

- Deburring edges of holes

- Enlarging holes

- Cutting grooves

Shape C: Cylindrical Ball Nose

This type of carbide burr shape is designed for detailed work. With a radius cut, the cylindrical ball nose carbide burr can cut narrow and tight spaces.

- Creating radius edges

- Cutting tops and sides

- Generating perfect transitions between curvatures

Shape D: Ball Shape

Ball-shaped carbide burrs are one of the most popular types of carbide burrs. The ball shape is perfect for engraving, micro-setting, and intricate carving.

- Carving

- Grinding

- Hole deburring

- Contouring

- Engraving

Shape E: Oval Shape

Oval-shaped carbide burrs are mainly used for creating rounded edges. They are also called egg-shaped burrs.

- Carving

- Enlarging holes

- Creating notches

- Deburring

- Chamfering

- Reshaping slots

- Creating intricate details

Shape F: Tree Radius End

As the name implies, a tree radius end carbide burr looks like a tree. It can be used to cut various materials like wood, plastics, and metal.

- Removing materials from a surface

- Grinding weld beads

- Grinding edges

- Reaching complex areas

Shape G: Pointed Tree Shape

Equipped with a sharp pointed head, the pointed tree carbide burr can create sharp grooves.

- Forming concave cuts

- Deburring curved corners

- Grinding narrow areas

Shape H: Flame Shape

A flame-shaped carbide burr looks similar to a flame. Like other carbide burr shapes, a flame burr also has a wide range of applications, including:

- Carving

- Grooving

- Enlarging holes

- Removing defects or unnecessary material

- Engraving intricate details

- Creating curves

Shape J: 60-degree cone

60-degree cone shaped carbide burrs are sharper than 90-degree cone burrs.

- Countersinking

- Creating notches

- Enlarging holes

- Deburring

- Creating intricate details

Shape K: 90-degree cone

Thanks to the cone shape, a 90-degree cone carbide burr can cut narrow and tight areas.

- Creating radius corners

- Creating conical countersinks

Shape L: Taper Radius End

The taper radius end shape is one of the most common carbide burr shapes that is widely used in various jobs.

- Creating conical holes

- Countersinking

- Creating radius corners on welds

- Forming flat and even transitions between two curvatures

Shape M: Cone Pointed Shape

Cone-pointed shaped carbide burrs can be applied to process various materials like wood, stainless steel, plastics, and more.

- Ideal for cutting narrow contours

- Working on rounded edges

- Surface processing

- Removing materials

Shape N: Inverted Cone

This specific carbide burr shape features a broad and flat end, gradually becoming narrower.

- Creating grooves and holes

- Accessing narrow and confined spaces

- Edge machining

- Generating undercuts

- Intricate tasks

- Deburring

Carbide burrs are Konetool’s featured products. With years of experience in manufacturing and supply of carbide burrs, we are confident in our outperformed burrs. If you are looking for a high-quality supplier, contact us today!