A Detailed Explanation of the Angle of Wood Turning Inserts

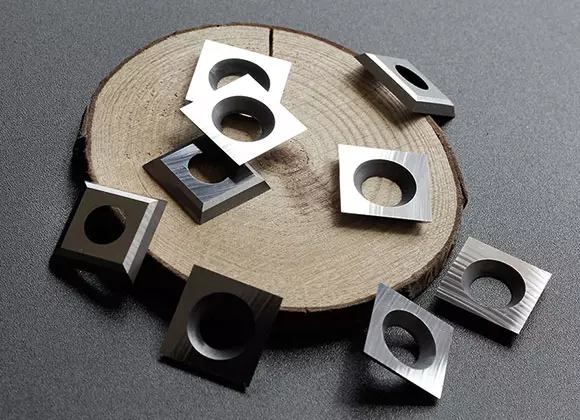

At present, cemented carbide blades have penetrated into various fields, especially in the woodworking field. Woodturning tools play an important role in wood cutting. During cutting, carbide woodturning tools cut into the workpiece, and the angle of woodturning inserts is of vital importance base used to determine the geometry of the cutting part of the tool.

1.The composition of the cutting part

The cutting composition of a woodworking tool can be compared to the phrase “3 sides, 2 turns, 1 point”. These include the head nut, the main edge, the second width, the main ring, the second edge, and the tip of the tools.

The rack face refers to the surface of the device through which chips can flow.

The main aspect refers to the surface of the tool in contrast and in interaction with the machining surface of the workpiece.

The secondary flange surface is the side surface of the tool that opposes and interacts with the machined surface in the workpiece.

The main cutting edge is the intersection line between the rake face and the main side

The secondary cutting edge represents the intersection line between the rack face and the second flange face.

The tooltip is the line of intersection between the main cutting edge and the auxiliary cutting edge. The tooltip is actually a small curve or straight line.

2. Auxiliary plane for measuring the angle of rotation of woodturning tool

To determine and measure the angle of woodturning inserts, three auxiliary planes are usually selected as references. The three velocity planes are section, base plane, and orthogonal plane.

This part represents a planar cut perpendicular to the plane of the tool holder tool at a selection point on the main side.

The base plane refers to the plane that passes through the selected point on the main surface and is parallel to the bottom of the shaft.

The orthogonal plane connects directly to the section and base plane in the plane.

3. Selection of main geometric angles and woodturning tools

The geometric angles of cement carbide woodturning tools include rack angles, relief angles, and detailed details of the angles of cement carbide woodworking tools.

The size of the rack angle corrects the difference between the rake and the rake head. First, select the angle of the stand according to the hardness of the recycled material. The workpiece is very strong and the angle of the stand is small, and vice versa. Secondly, depending on the method of treatment, the angle of impact must be taken into account. For speed, the angle of the stand should be small, and for decoration, the angle of the stand should be large.

When selecting backward angles, processing characteristics must be taken into account first. Precision machining has a higher clearance angle and rough machining has a lower cleaning angle. Second, consider the hardness of the workpiece. The hardness of the treated material is high and the rear angle should be small to increase the strength of the cutting head, otherwise, the rear angle should be the smallest. The permeable angle is usually not zero or negative, it is usually between6 ° and 12°.

The choice of woodturning insert angle is very important to the overall performance of the woodturning tool. When choosing the carbide woodturning tool to use, you must choose the appropriate turning tools according to the workpiece.