Circular Saw Blade Basics

Circular saw blades are frequently used cutting tools that can be mounted on various sawing machines, such as circular saws, table saws, miter saws, and panel sizing saws, just to name a few. They are capable of cutting a variety of materials, including wood, metal, plastics, and more. With the right blade, you’ll get a smooth and quality cut. There are a few things to consider when selecting, including sizes, tooth count, tooth geometry, gullet, anti-kickback, and hook angle. So, it is quite confusing and frustrating to choose the most suited blade for your job. Don’t worry! In this article, we’ll dive into circular saw blade basics and discuss all the things you need to know about getting the right blade.

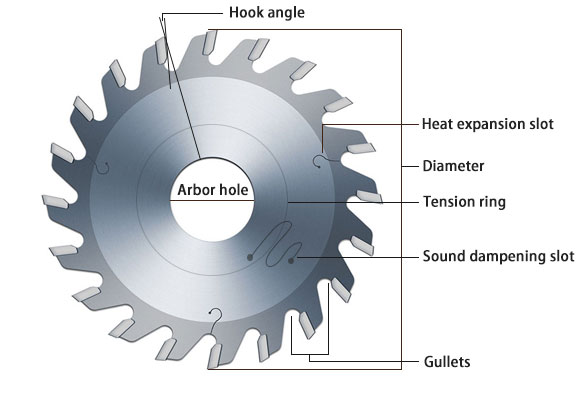

Diameter

The diameter of a circular saw blade typically ranges from 100 mm (4”) to 300 mm (12”). It affects the RPM and the depth of the cut. When selecting a blade, you can see the diameter printed on the face of the blade.

Arbor hole

The arbor hole is the center hole of the blade, which allows your blade to be mounted to your saw machine. The most common diameter of the arbor hole is 5/8” for the blade with a diameter of 10”. The arbor hole can be larger than the bore shaft, but you need a reducer ring to fit the blade into the shaft.

Kerf

Understanding the kerf is essential for selecting the right blade for a particular task and for making precise cuts. Kerf refers to the width of the cut made by a blade and it also defines the thickness of a blade. There are three types of kerf: full kerf, thin kerf, and ultra-thin kerf. A full-kerf blade is a circular saw blade with 1/8” (3.175mm) wide carbide teeth. A thin-kerf blade features 3/32” (2.38mm) wide teeth. An ultra-thin kerf blade has 1/20” (1.35mm) or less wide teeth. Full-kerf blades are suitable for heavy-duty projects, cutting thick and dense hardwood. A thinner kerf means less material waste and creates more precise cuts.

Tooth Count

To put it simply, blades with more teeth result in smoother and cleaner cuts, while blades with fewer teeth leave faster and rougher cuts. Ripcut blades with a 7-1/4” diameter are usually equipped with 24 teeth, and larger blades may have more teeth depending on the blade’s size and application. As for 7-1/4” diameter crosscut blades designed for a table saw, 40 to 60 teeth are most common, but blades for other types of saw machines such miter saws and radial arm saws require larger blades with more teeth, such as 80, 90, 100. A 7-1/4” circular saw blade with 24 to 40 teeth is known as a general-purpose blade or a combination blade.

Tooth Grind

Tooth grind refers to the shape of the individual cutting teeth on a circular saw blade which can directly affect the cutting performance. There are various types of tooth grinds designed for different purposes. When selecting a blade, make sure the specific application of each type of blade. Some common types of tooth grinds include:

- Flat Top Grind (FTG)

FTG blades feature teeth with a flat top and a square shape, suitable for ripping and fast, rough-cutting applications.

- Triple Chip Grind (TCG)

TCG blades feature teeth with alternating flat-top and beveled-top teeth. The beveled tooth roughs out a cut and then the flat-top tooth cleans it up. TCG is often used for cutting dense materials, including plastics, aluminum, solid surface, etc.

- Alternate Top Bevel Grind (ATB)

This type of grind features teeth that alternate between a left-leaning and right-leaning bevel, creating a sharp point at the top of each tooth. ATB blades can create clean cuts thanks to the shape of the teeth, causing shear cuts. ATB blades are often called general purpose and ideal for crosscutting on solid wood, melamine, veneers, and plywood.

- Alternate Top Bevel with Raker (ATBR)

ATBR blades are equipped with several (usually 10) sets of 5 teeth (4 alternating beveled teeth or ATB, followed by a raker tooth or FTG). ATB teeth slice through the wood fibers and the FTG tooth help remove sawdust. ATBR blades are also regarded as all-purpose blades due to their tooth grind and are perfect for crosscutting.

Overall, the choice of tooth grind for a circular saw blade will depend on the specific cutting application and the material being cut. Different tooth grinds can affect the speed, quality, and precision of the cut, so it’s important to choose the right blade for the job.

Hook angle

Hook angle or rake angle refers to the angle between the saw blade’s teeth and the plane of the blade’s rotation. It is the angle at which the teeth are bent forward or backward in relation to the blade’s centerline. The hook angle can be positive or negative or zero. The hook angle affects the cutting performance of the saw blade. With a more positive hook angle, the blade can create more aggressive cuts.

Positive hook angle: Blades with positive hook angle have teeth that are angled forward in the direction of rotation. With a more aggressive cutting action, a positive hook angle is ideal for ripping and cutting thicker workpieces. However, if not properly used, a positive hook angle can be dangerous for causing kickback or grab. Blades with a hook angle between 5 to 20 degrees can be used for general ripping or crosscutting. A more than 30-degree hook angle is suitable for cutting veneered plywood or melamine-coated particleboard.

Negative hook angle: Contrary to a positive hook angle, negative hook angle teeth are angled backward, creating slower and more controllable cutting action with little risk of kickback. It is ideal for finer and crosscutting projects and can leave a cleaner and smoother finish. Miter saws and radial arm saws need a negative hook angle (-5 to -10 degrees).

Zero hook angle: Blades with a zero hook angle have carbide teeth that are perpendicular to the blade’s centerline. It is required in portable circular saws and non-sliding miter saws.

Heat Expansion Slot

A heat expansion slot is a laser-cut slot or notch that is cut into the body of a circular saw blade, allowing for blade expansion from heat buildup during operation. It helps ensure the safety and longevity of the blade while also improving cutting performance.

Sound Dampening Slot

Similar to the heat expansion slot, a sound-dampening slot is also a laser-cut slot that is cut into the steel body of the circular saw blade, but it is used to reduce the amount of noise and vibration produced during use. The sound-dampening slot is usually filled with a material like resin or a rubber-like substance.

Tension Ring

A tension ring is a visible ring on the steel body of a circular saw blade, helping maintain the proper tension and flatness of the blade during operation. It prevents the blade from bending or warping. The tension ring is especially required in high-speed or heavy-duty applications.

Anti-kickback

Anti-kickback is a safety feature designed to prevent the blade from “grabbing” or kicking back during cutting. This design comprises a series of raker teeth, helping limit the depth of cut. Anti-kickback is a very important safety design for a circular saw blade, reducing the risk of injury and damage to the saw and the cutting material.

Gullet

Gullets are the curved spaces between the teeth of a blade. They are designed to help remove sawdust and chips. The size and shape of the gullets can vary depending on the type and size of the saw blade and the cutting material. Larger gullets can remove more sawdust and improve cutting efficiency, reducing the risk of overheating. But the risk of vibration is increased. Smaller gullets improve cutting accuracy but are not as efficient at evacuating sawdust.

RPM

RPM is a commonly known term, referring to revolutions per minute. Please note that the RPM is not an accurate indicator of the cutting speed of a blade. The number of teeth and the diameter size of the blade are the key factors that determine the cutting speed. RPM is extremely important safety information. When selecting a blade, make sure that the max. The RPM of your saw machine is less than the max. RPM of the blade. Blades with a higher RPM work efficiently, but can produce more heat, while blades with a lower RPM runs less efficiently, but can reduce the risk of overheating.

Conclusion

Selecting a proper circular saw blade can be quite complex. There are too many factors to consider. However, if you read our tips carefully, we believe that you will be less confused. Konetool is an experienced supplier of industrial circular saw blades. Request a quote for further information (minimum order quantity, price, delivery, payment, etc).