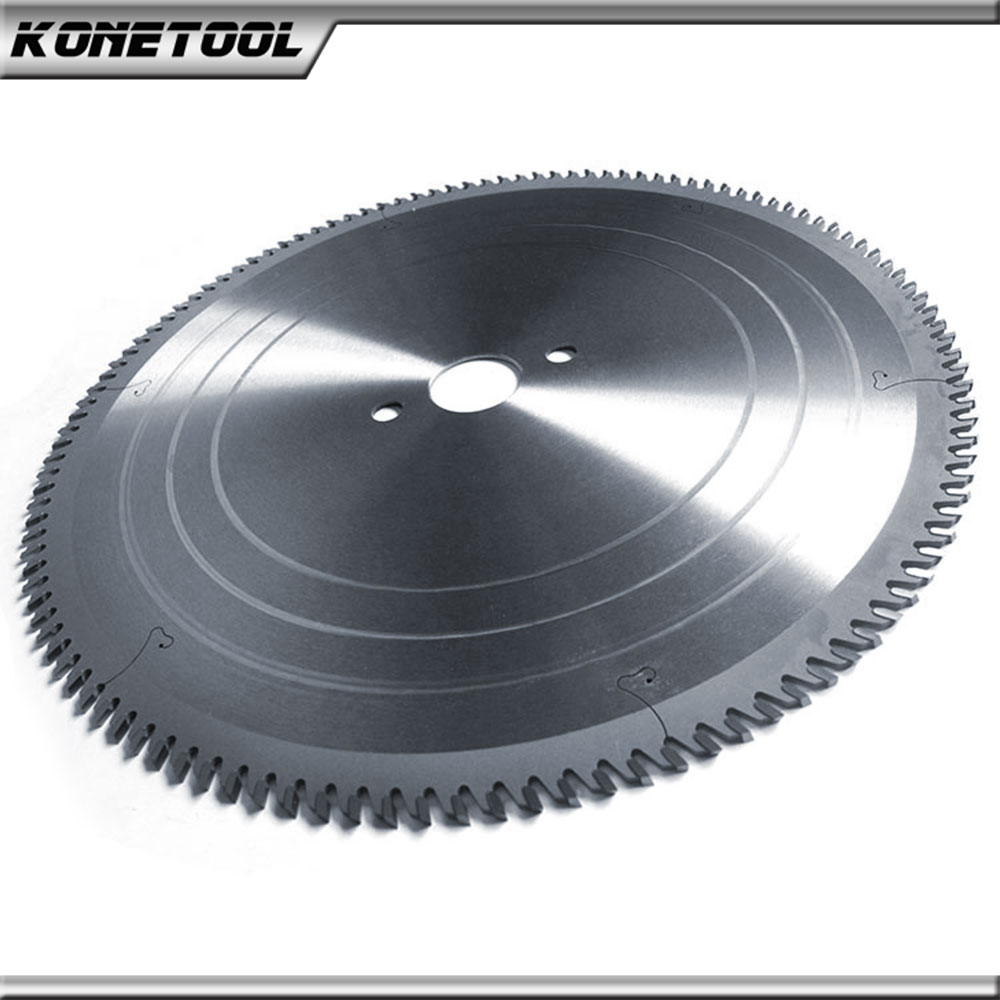

Konetool manufactures and supplies industrial-quality TCT cold saw blades for grooving aluminum for industrial applications like metal fabrication.

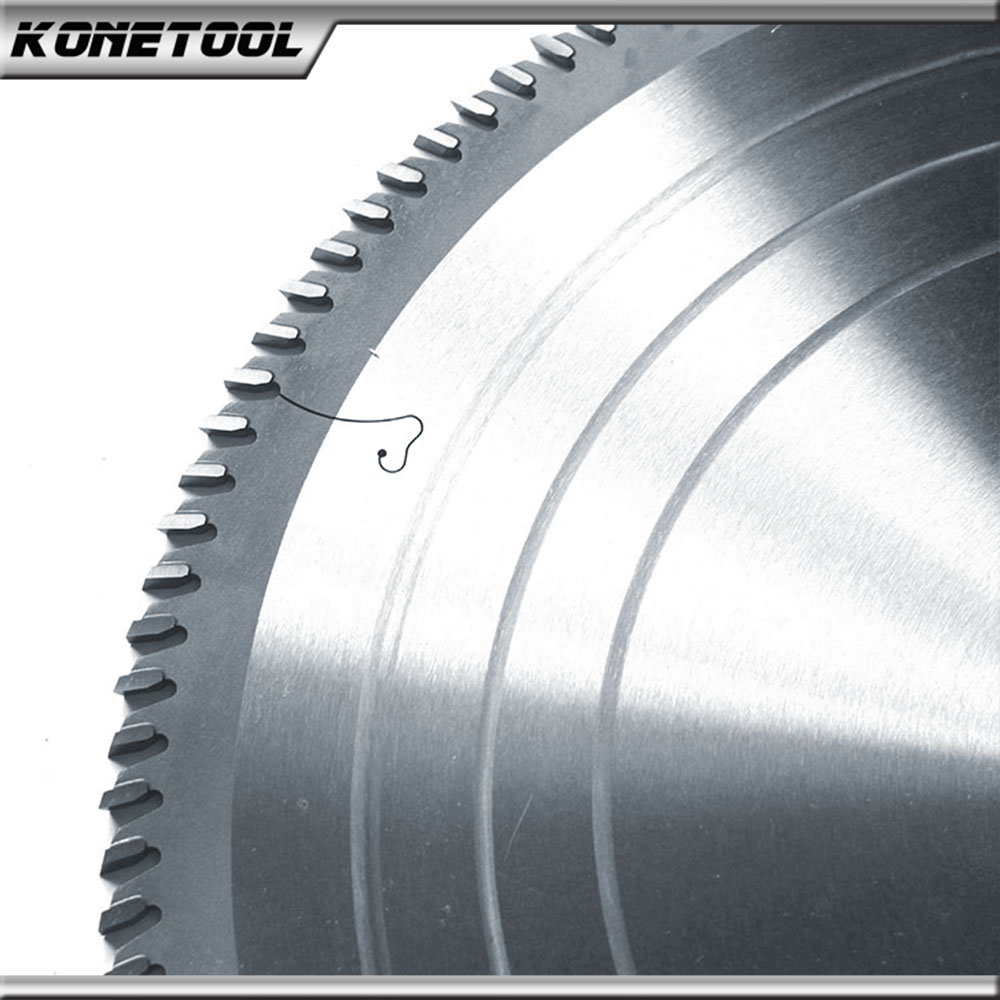

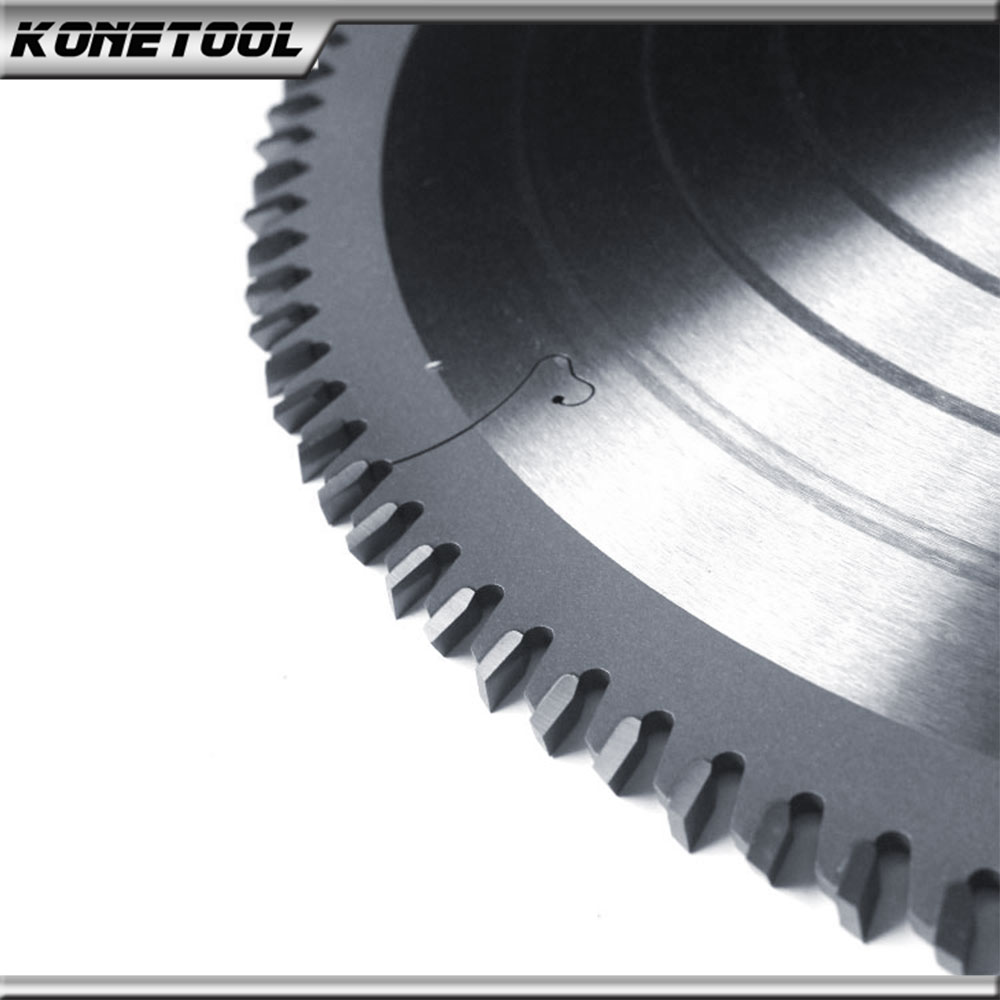

Tooth Geometry: Square teeth – “FZ”

Cutting Material: Aluminum, brass, copper, and other non-ferrous metals

Machines: Horizontal panel saws, slotting devices, double milling machines, etc

Request a quote for further information (MOQ, price, delivery, etc).