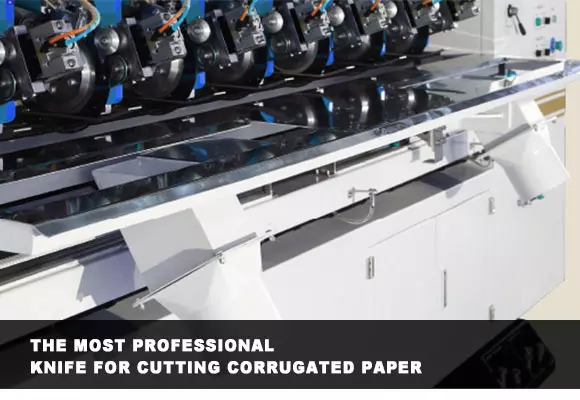

Tungsten Carbide Corrugated Slitter Blades: The Most Professional Knife For Cutting Corrugated Paper

With the development of the economy and the convenience of transportation, the express delivery industry is becoming more and more common. When you receive a courier, do you feel a touch of beauty from this neat tailoring process? From this perspective, paper slitter blades are of great importance. And its quality will directly affect the quality of the paper cutter, and ultimately affect the entire paper cutting process. Next, I will give you a brief introduction to the paper cutter blade.

The Paper cutter blade is one of the important parts of a paper cutter, which is widely used in cutting corrugated paper industry. Corrugated knives are used for slitting corrugated paper. Slitting is an important process in the production of corrugated paper.

Corrugated slitter blades are mostly used in corrugated paper slitting equipment. Each piece of equipment is about 5-6 pieces, and the number of blades varies according to equipment. The sharpness and service life of the blade greatly affect the working efficiency of the equipment.

These blades are divided into two types: tungsten carbide and high-speed steel (HSS), which are sharp and durable. Tungsten carbide paper cutting blade is composite rolling and can be used for general cutting. Original crystal grain is more refined, and chipping resistance is strong. The combination of blade and cutter body has no defects such as transition and voids. It can cut things that are difficult to cut by ordinary blades, such as cellophane and high-gram copper paper. It enjoys a good reputation at home and abroad, and its product specifications are complete.

We need to pay attention to the following points in use:

1. Use effect and life of corrugated knives

When using automatic paper cutters, CNC paper cutters, program-controlled paper cutters, or other paper cutters, paying attention to operation techniques can improve the efficiency and service life of cutter blades.

2. Materials of corrugated knives

Quality of material is very important for paper cutter blades. To achieve high performance of paper cutter blade, reform of material is a critical step. The quality of the paper cutter blade will not only affect the performance of the blade but also affect its service life. A tungsten carbide paper cutter blade is made from tungsten carbide. Its service life is several times that of general blade material. Cutting material and speed range are also much better than normal. Therefore, in order to improve the processing accuracy of carbide paper cutter blades, high-quality surface quality must carefully consider the material selection of the blade. In short, the material of the blade is very important.

3. Grinding angle of corrugated paper cutter blades

Corrugated knives can be reground, and the angular mesh of the grinding wheel has a direct effect on blade after refining.

Single-sided paper cutter blade is a single-edged blade, and blade grinding angle is ∠19°~23°. Grinding edge of this shape makes bevel surface of blade bear pressure of paper corner during cutting, and blade’s edge is quickly worn. Double-sided blade has good wear resistance, and grinding edge can reduce load of paper cutter and improve accuracy of paper cutting. When the material of the paper cutter blade is right, considering the cutting resistance of paper, and angle of the grinding edge should be less than ∠19°~23°.

4. Quality of paper cutter blade grinding

When grinding the blade, the higher the grinding finish, the lower the cutting resistance, the longer the service life of the paper cutter blade, and the better cutting quality.

5. Cutting speed of carbide paper cutter blades

The cutting speed of carbide paper cutter blades mainly depends on the material being processed and the diameter of the blade. Instructions for selecting the cutting speed of carbide paper cutter blades are also available for reference.

In addition, the cutting parameters of cemented carbide corrugated cutters are also affected by various factors such as machine tools, tool systems, and tool materials. It should be selected according to the actual situation, and the cutting speed should be selected according to the experience accumulated by the operator for many years. If you have any questions, you can consult our professional salespeople.