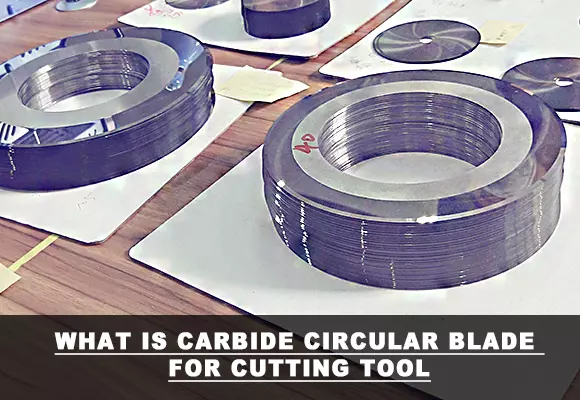

What is A Carbide Circular Blade for the Cutting Tool?

Tungsten carbide circular blades are made from cemented alloy. Cemented carbide is an alloy material made from refractory metal compounds and bonded metal. Cemented carbide covers a series of outstanding properties. For example, high hardness, great strength and toughness, nice heat resistance, and corrosion resistance. Especially, the hardness and wear resistance of cemented carbide are unchanged even at 500℃ and even at high temperatures as 1000℃.

A carbide circular knife for the cutting tool is also called a tungsten carbide circular blade. Carbide circular blade is largely used in a variety of fields and is an essential cutting tool in the industry. Characteristics of cemented carbide material itself determine the importance of safe operation of cemented carbide blade for the cutting tool. Please take protective measures before installing the blade to prevent the carbide circular blade for the cutting tool from falling and causing unnecessary personal and property safety losses.

Auditory inspection

When installing a tungsten carbide circular blade, please use your right index finger to carefully lift the blade and hang the blade in the air, then tap the carbide circular blade round shape with a wooden hammer, and listen to the sound on the blade, like a dull blade, experience It is proved that cutter body is often damaged by external force impact and there are cracks and damages. Such blades should be banned immediately. It is forbidden to use a foot cutter blade that emits a dull sound!

Blade installation

Before installing the blade, please carefully clean dust, chips, and other debris on the mounting surface of the rotary bearing of the cutting machine, and keep the bearing installation surface and cutting machine clean.

1. Place the carbide circular knife for the cutting tool on the mounting surface of the bearing carefully and steadily, and turn the bearing of the cutting machine by hand to automatically align it with the center of the carbide circular blade for cutting tool.

2. Install the press block on the blade of the foot cutter and align its bolt hole with the bolt hole on the bearing of the foot cutter.

3. Install hexagon socket bolts, and tighten screws with a hexagon socket wrench to firmly install the blade on the bearing.

4. After the blade is installed, there should be no looseness or deflection.

Safety protection

After the tungsten carbide circular blade is installed, a safety shield and other protective devices on the foot cutting machine must be installed in place before starting foot cutting machine and have a real protective effect ( blade workshop on the foot cutting machine should be surrounded by a safety baffle, Steel plate, rubber, and other protective layers).

Operating speed

The working speed of the foot cutter should be limited to 4500 rpm or less. It is strictly forbidden to operate a cutting machine at an excessive speed!

production efficiency

A prerequisite for production efficiency is the same safe operation. The cutting operator must follow relevant use requirements to make the cutting machine blade work safely on the cutting machine.