Description

A cold saw, as the name suggests, is a saw machine that can keep the saw blade and cutting material cool during operation, because it transfers the heat and energy to the chip. Cold saws are ideal for processing most ferrous and non-ferrous metals. A flood coolant system and lubricants are needed during the cutting process.

Cold saw blades are circular saw blades for metal cutting, including solid high speed steel (HSS) and tungsten carbide tipped (TCT). TCT blades are used for cutting non-ferrous metal at first but can perform well with cutting ferrous metal as well. TCT cold saw blades consist of a steel blade body with tungsten carbide inserts brazed to the tips. Tungsten carbide tips must be precisely ground to provide perfect cutting and clearance angles. Tungsten carbide is more high-temperature-resistant than HSS, so TCT cold saw blades can run at a higher speed, resulting in high efficiency. Besides, tungsten carbide inserts are extremely wear-resistant, so TCT blades have a longer service life than HSS blades.

Konetool has been dedicated to TCT cold saw blade manufacturing for over 10 years. Our carbide cold saw blades are designed for specialist machines to guarantee enhanced efficiency with requested cutting performance. With our 100% virgin materials, full CNC production lines, and rigorous quality inspections, we have full confidence in our TCT cold saw blades.

KONETOOL TCT Cold Saw Blade Features:

- Saw blade bodies are manufactured from the highest quality steel to guarantee stable work of the saw machine even in extreme conditions;

- Saw plates are very flat thanks to well heat treatment;

- Flattening and surface grinding ensure that the plate is distortion-free and has a uniform thickness;

- High rigidity ensures straight running during operation;

- 100% virgin tungsten carbide material;

- The TCG tooth configuration is durable and has a low chip out when processing brittle materials;

- Carbide teeth are ground to extremely high precision and can be reground several times;

- Precise and clear cuts;

- Advanced brazing technology prevents carbide tips from breaking

- The coating extends service life and ensures stable performance.

Request a quote for further information (MOQ, price, delivery, etc) if you are interested in our TCT cold saw blades. Our salespeople and engineers are ready to provide the most cost-efficient solutions for you.

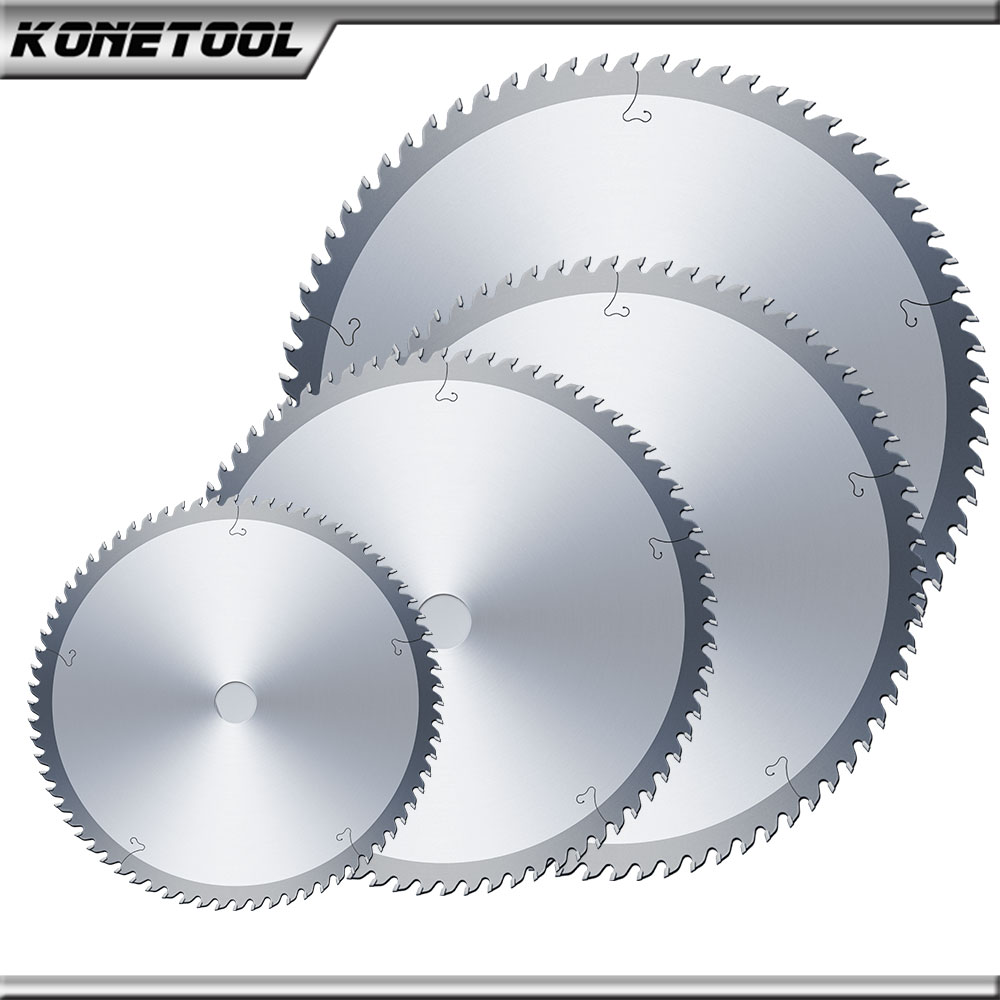

Specification:

| D (mm) | d (mm) | B (mm) | Z | TF |

| 255 | 25.4/30 | 2.8 | 100 | TCG |

| 305 | 25.4/30 | 3.0 | 120 | TCG |

| 450 | 30 | 4.0 | 120 | TCG |

| 500 | 30 | 4.4 | 120 | TCG |