Description

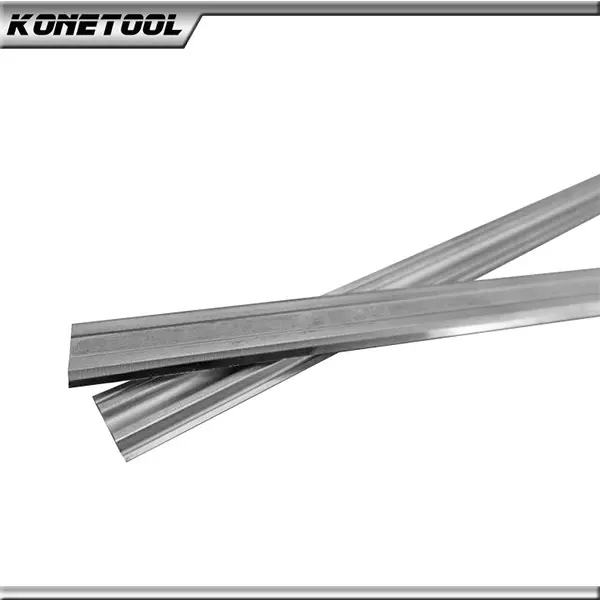

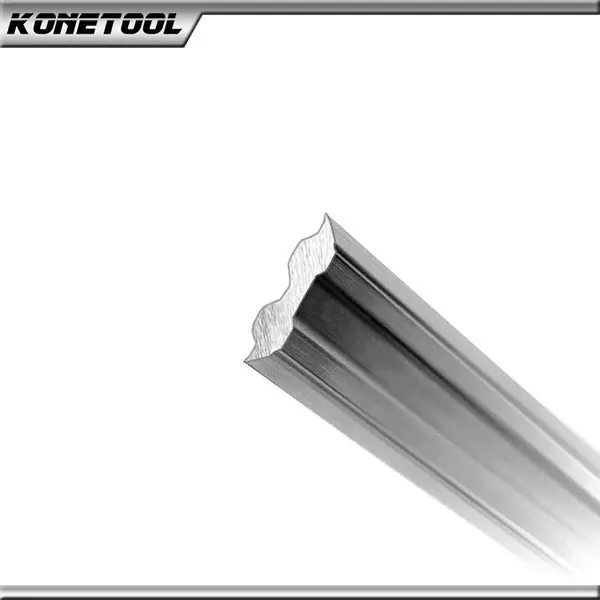

The Tersa system is recognized as the planing tool market leader famous for quick-changing planer knives. Tersa knives can be changed easily without requiring special tools. In addition, Tersa knives are well-known for their precision and durability, making them perfect for use in high-end woodworking applications where quality is significant. Thanks to minimal knife protrusion, Tersa planer blades create low noise during operation.

Konetool, an ISO-certified manufacturer, offers high-quality double-sided and disposable Tersa planer knives for planers, jointers, molders, and shapers. We have over 10 years of experience in manufacturing premium Tersa knives. Our customers are furniture factories, woodworking workshops, and precision tool distributors/wholesalers/trades from different countries.

If you’re looking for quality Tersa knives, please feel free to contact us or directly request a quote on this page. Our salespeople are honored and ready to help you.

The following are the specifications of solid carbide Tersa knives and HSS Tersa knives.

1. Solid Carbide Tersa Knives

Compared to high-speed steel, solid carbide is more brittle, but it features an 8-10 times longer service life and is ideal for cutting hardwood and glue lines. The surface of our Tersa knives is perfectly polished, resulting in an excellent mirrorlike cutting finish.

Grade:

| Konetool Grade | Grain Size | Density (g/cm³) | Hardness (HRa) | T.R.S (N/m㎡) |

| GF21 | Fine | 14.85-15.05 | 91 | 2000 |

| TF21 | Sub-Micron | 14.96 | 92.8 | 2250 |

| TF25 | Sub-Micron | 14.52 | 91.8 | 2950 |

| GS25 | Sub-Micron | 14.4 | 91.7 | 3200 |

Suitable for cutting:

Hardwoods (teak, hickory), exotic woods, man-made materials with glue lines (laminated woods)

Specification:

| Length (mm) | Width (mm) | Thickness (mm) | Cut Angle (α°) |

| 50 | 10 | 2.3 | 35 |

| 60 | 10 | 2.3 | 35 |

| 70 | 10 | 2.3 | 35 |

| 80 | 10 | 2.3 | 35 |

| 85 | 10 | 2.3 | 35 |

| 90 | 10 | 2.3 | 35 |

| 100 | 10 | 2.3 | 35 |

| 110 | 10 | 2.3 | 35 |

| 115 | 10 | 2.3 | 35 |

| 120 | 10 | 2.3 | 35 |

| 125 | 10 | 2.3 | 35 |

| 130 | 10 | 2.3 | 35 |

| 140 | 10 | 2.3 | 35 |

| 150 | 10 | 2.3 | 35 |

| 155 | 10 | 2.3 | 35 |

| 160 | 10 | 2.3 | 35 |

| 170 | 10 | 2.3 | 35 |

| 180 | 10 | 2.3 | 35 |

| 185 | 10 | 2.3 | 35 |

| 190 | 10 | 2.3 | 35 |

| 200 | 10 | 2.3 | 35 |

| 210 | 10 | 2.3 | 35 |

| 220 | 10 | 2.3 | 35 |

| 230 | 10 | 2.3 | 35 |

2. HSS Tersa Knives

HSS Tersa knives have better high-temperature resistance and feature higher cutting efficiency and longer service life than carbon steel blades. Konetool HSS Tersa knives create an outstanding finish and are ideal for cutting resinous types of wood.

Suitable for cutting:

Softwoods (Douglas Fir, Cedar, Pine, Larch), hardwoods (Oak, Tulipwood, Birch, Cherry, Maple)

Specification:

| Length (mm) | Width (mm) | Thickness (mm) | Cut Angle (α°) |

| 50 | 10 | 2.3 | 35 |

| 60 | 10 | 2.3 | 35 |

| 70 | 10 | 2.3 | 35 |

| 80 | 10 | 2.3 | 35 |

| 85 | 10 | 2.3 | 35 |

| 90 | 10 | 2.3 | 35 |

| 100 | 10 | 2.3 | 35 |

| 110 | 10 | 2.3 | 35 |

| 115 | 10 | 2.3 | 35 |

| 120 | 10 | 2.3 | 35 |

| 125 | 10 | 2.3 | 35 |

| 130 | 10 | 2.3 | 35 |

| 140 | 10 | 2.3 | 35 |

| 150 | 10 | 2.3 | 35 |

| 155 | 10 | 2.3 | 35 |

| 160 | 10 | 2.3 | 35 |

| 170 | 10 | 2.3 | 35 |

| 180 | 10 | 2.3 | 35 |

| 185 | 10 | 2.3 | 35 |

| 190 | 10 | 2.3 | 35 |

| 200 | 10 | 2.3 | 35 |

| 210 | 10 | 2.3 | 35 |

| 220 | 10 | 2.3 | 35 |

| 230 | 10 | 2.3 | 35 |

| 240 | 10 | 2.3 | 35 |

| 250 | 10 | 2.3 | 35 |

| 260 | 10 | 2.3 | 35 |

| 265 | 10 | 2.3 | 35 |

| 270 | 10 | 2.3 | 35 |

| 280 | 10 | 2.3 | 35 |

| 290 | 10 | 2.3 | 35 |

| 300 | 10 | 2.3 | 35 |

FAQ:

- How can I make the payment?

We accept various payment methods, including T/T (bank transfer), PayPal, Western Union, and L/C (Letter of Credit) for larger orders. Payment terms are typically 30% deposit in advance and 70% balance before shipment. - What are the shipping options and delivery times?

We support FOB, CIF, and DDP shipping terms depending on your preference. we usually ship via express courier like DHL, FedEx, or UPS. Lead time for bulk orders is generally 15–35 days, depending on quantity and customization requirements. - How do you ensure product quality?

We have a strict quality control system in place. All products are inspected at every stage of production, We have own quality inspection team and laboratory, along with advanced equipment to ensure the qualification rate of our products up to 99%.and can provide test reports or certificates upon request. - Can I customize the product or packaging?

Yes, we offer OEM and ODM services. You can customize the product design, . Just let us know your requirements,CAD,Step Drawings,or send sample Our team will assist you throughout the process. - What is your after-sales service policy?

If you encounter any quality issues, please contact us with photos or videos. We will evaluate the situation and provide replacements, spare parts, or refunds as appropriate.